PCC PANEL

PCC PANEL - Main Power Control Panel which consists of feeder breakers and supply breakers, monitoring devices and control devices. A motor control center can also include more switch gears, a lot of switchgears like this.

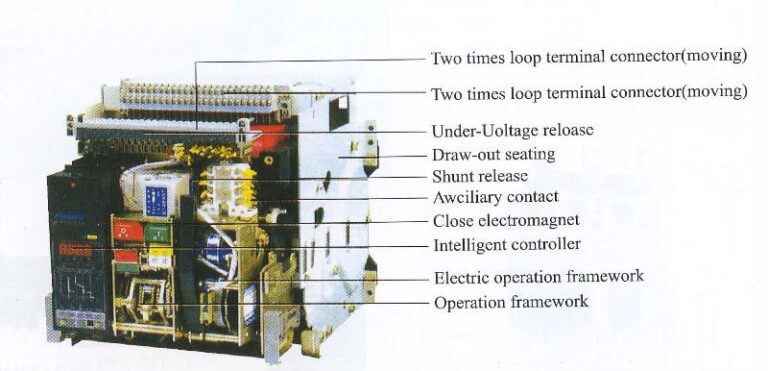

ACB (AIR CIRCUIT BREAKER)

ACB (AIR CIRCUIT BREAKER) - A circuit breaker is used for the switching mechanism and protection of the system. AIR CIRCUIT BREAKER, Make or break a circuit manually or by remote control under normal conditions. AIR CIRCUIT BREAKER, Break a circuit automatically under fault conditions (like over current, Short circuit, etc). AIR CIRCUIT BREAKER, Make a circuit manually or by remote control under the fault conditions. AIR Circuit breakers are widely used in industries as well as power systems for controlling and protection of different parts of the circuit like switch gears, Transformers, Motors, Generators/Alternators, etc. AMPERE RATING UP TO 800A TO 6300A. An air circuit breaker for a low voltage less than 1000 v power distribution switchgear.

ACB Working – Air Circuit breakers generally have two pairs of contacts. The main pair of contacts (1) carries the current at normal load and these contacts are made of copper metal. The second pair is the arcing contact (2) and is made of carbon. When the circuit breaker is being opened, the main contacts open first. When the main contacts open the arcing contacts are still in touch with each other. As the current gets a parallel low resistive path through the arcing contact. During the opening of main contacts, there will not be any arcing in the main contact. The arcing is only initiated when finally the arcing contacts are separated. Each of the arc contacts is fitted with an arc runner which helps. The arc discharge moves upward due to both thermal and electromagnetic effects as shown in the figure. As the arc is driven upward it enters the arc chute, consisting of splatters. The arc in the chute will become colder, lengthen, and split hence arc voltage becomes much larger than the system voltage at the time of operation of the air circuit breaker, and therefore the arc is extinguished finally during the current zero. The air brake circuit box is made of insulating and fireproof material and it is divided into different sections by the barriers of the same material, as shown above, figure (a). At the bottom of each barrier is a small metal conducting element between one side of the barrier and the other. When the arc, driven upwards by the electromagnetic forces, enters the bottom of the chute, it is split into many sections by the barriers, but each metal piece ensures electrical continuity between the arcs in each section, the several arcs are consequently in the series.

ACB CONSTRUCTION EXTRANAL

- OFF button (O)

- ON button (I)

- Main contact position indicator

- Energy storage mechanism status indicator

- Reset Button

- LED Indicators

- Controller

- “Connection”, “Test” and “isolated” position stopper (the three-position latching/locking mechanism)

- User-supplied padlock

- Connection “,” Test “and” separation “of the position indication

- Connection (CE) Separation, (CD) Test (CT) Position indication contacts

- Rated Name Plate

- Digital Displays

- Mechanical energy storage handle

- Shake (IN/OUT)

- Rocker repository

- Fault trip reset BUTTON

ACB CONSTRUCTION INTERNAL

- Sheet Steel Supporting Structure

- Current Transformer for Protection Trip Unit

- Pole Group insulating box

- Horizontal rare terminals

- Plates for fixed main contacts

- Plates for fixed arcing Contacts

- Plates for Main moving contacts

- Plates for Moving Arcing contacts

- Arcing Chamber

- Terminal box for fixed version – Sliding Contacts for withdraw able version

- Protection Trip Unit

- Circuit breaker Closing and Opening Control

- Closing Springs

- Plain Break Type Air Break Circuit Breaker or Cross-Blast ACB

- Magnetic Blowout Type Air Break Circuit Breaker

- Air Chute Air Break Circuit Breaker

- Air Blast Circuit Breaker

- BUS-COUPLER-Bus coupler is a device which is used to couple one bus to the other without any interruption in

power supply and without creating hazardous arcs.

Busbar

BUSBAR - An electrical busbar as a conductor or a group of conductors used for collecting electric power from the incoming feeders and distributing them to the outgoing feeders. The most common of the bus-bars are 40×4mm (160 mm2); 40×5 mm (200 mm2); 50×6 mm (300mm2); 60×8 mm (480 mm2); 80×8 (640 mm2) and 100×10 mm (1000 mm2). Busbar is available in rectangular, cross-sectional, round, and many other shapes. The rectangular bus bar is mostly used in the power system. Copper and aluminum are used for the manufacturing of the electrical bus bar.

Changeover

CHANGEOVER – A transfer switch is an electrical switch that switches a load between two sources.

Insulator

INSULATOR – A material of such low conductivity that the flow of current through it is negligible. Material, often glass or porcelain, in a unit form designed so as to support a charged conductor and electrically isolate it. a person or thing that insulates.

Heat Shrinke Sleeve

HEAT SHRINKE SLEEVE – Heat Shrinkable Sleeve (or commonly “shrink sleeve”) is a corrosion protective coating for BUSBAR in the form of a wraparound or tubular sleeve that is field-applied.